Herringbone floor

Classification:

SPC Floor

Key words:

SPC Floor

SPC lock floor is composed of thick wear-resistant layer, UV layer, color film texture layer and substrate layer. European and American countries call this kind of floor RVP(rigid vinyl plank), rigid plastic floor. Its base material is made of stone powder and thermoplastic polymer materials after mixing evenly and then made of high-temperature extrusion composite board, both wood and plastic properties and characteristics, to ensure the strength and toughness of the floor.

Unlike wood-plastic flooring (WPC), stone crystal flooring (SPC) does not contain any wood chips, the core substrate is denser, and the performance is harder and more stable. Therefore, there are domestic SPC manufacturers also called it "diamond board".

Therefore, the thicker the thickness of the spc floor, the more materials used, the higher the price will be. Thickness production is also related to technology. Many people have made very thin floors in order to pursue low-cost products for engineering use. However, too thin a thickness will greatly reduce the performance and stability of the products. There may be no problem at that time. Once the temperature difference is high and low, or other harsh environmental tests, various quality problems will occur sooner or later. Little Blue Whale Crystal suggests using more than 4mm for engineering decoration and more than 5mm for home decoration, product performance is more stable and durable, and also supports floor heating.

Workshop equipment

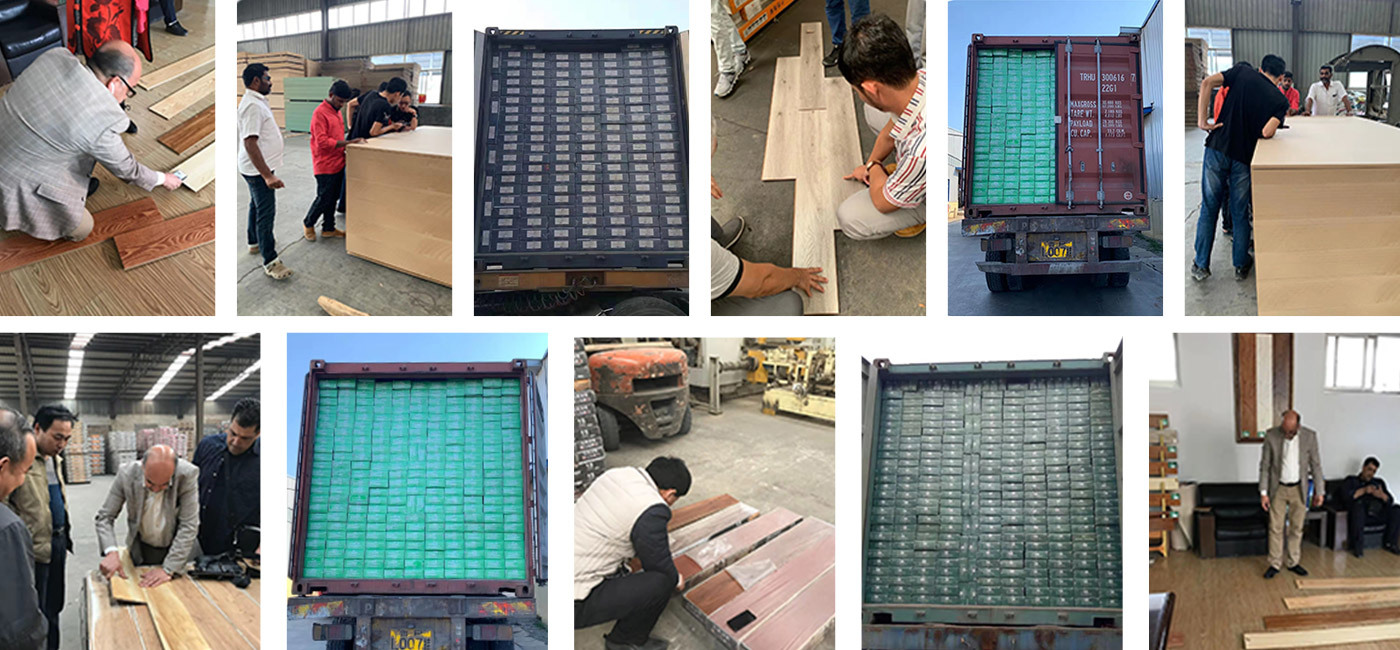

Packaging and delivery

Appearance of the factory

Related Products

online message